BGMZ LLC offers automation and instrumentation for comprehensive protection of PC pumps from the "dry running", excess pressure from the norm at the outlet of the pump and vacuum at the inlet.

The package includes:

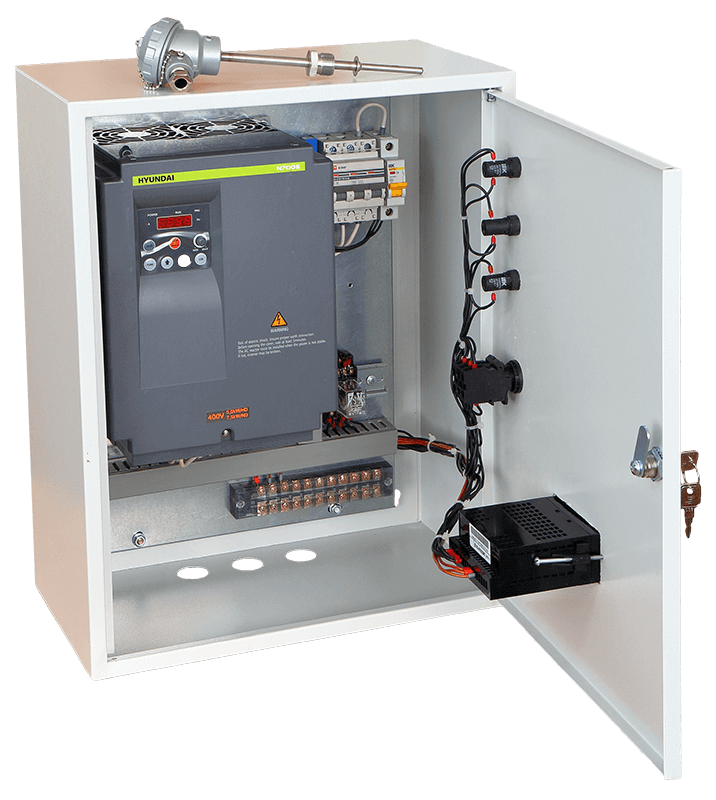

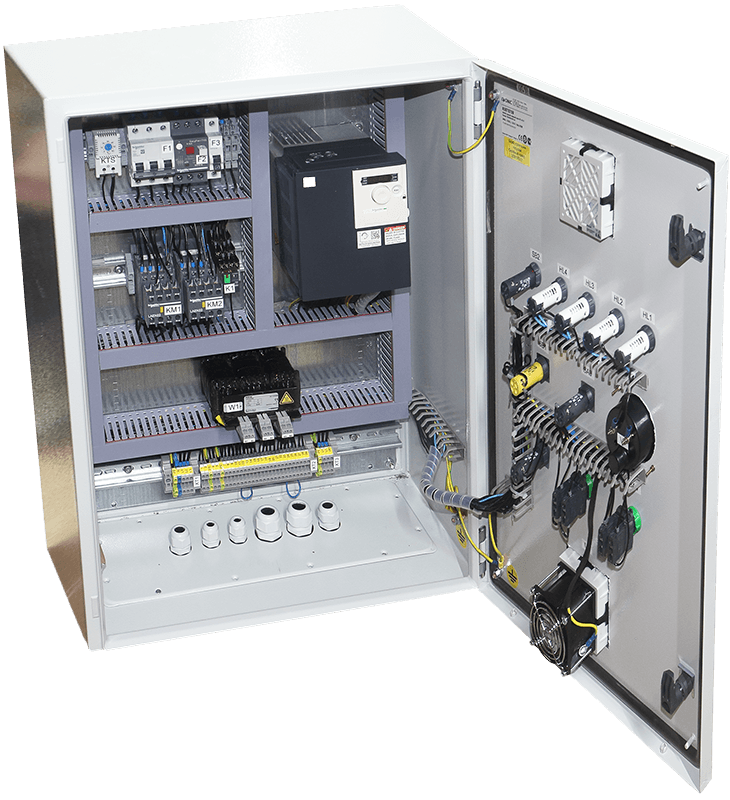

- control cabinet with automatics, gauges-regulators, control buttons and signal lamps;

- temperature sensor, common industrial (explosion-proof) design;

- pressure sensor, common industrial (explosion-proof) design;

- discharge sensor, common industrial (explosion-proof) design for work in difficult field conditions.

The most frequent reason for a single-screw pumping unit to come out of standing is pump operation on a “dry running”.

The most frequent reason for a PC pump to come out of standing is pump operation on a “dry running”.

“Dry running” is the mode of operation of a PC pump during which the working medium is not pumped through the pump. This mode is extremely undesirable and emergency, it shortens the life of the PC pump and leads to breakage of the pump unit.

The working fluid pumped by the pump is at the same time lubricating and cooling liquid. Without it, the rotor and stator overheats and fails. When operating in the “dry running” mode, the working elements of the pump can be deformed and fail. To ensure long and reliable operation of the pump, it should not be allowed.

To protect the pump from dry running, automatics are used: «Dry-running protection system». It will turn off the pump when dry running. The system consists of a temperature sensor (thermocouple), a single-channel position controller (thermostat), and a control cabinet.

The principle of such a system is as follows:

- in the absence of the pumped medium in the rotor and stator, the temperature rises under the action of friction. The temperature limit value is set manually by the operator on the thermostat. When the upper temperature limit is reached - “System” disconnects the pump unit from the electrical supply.

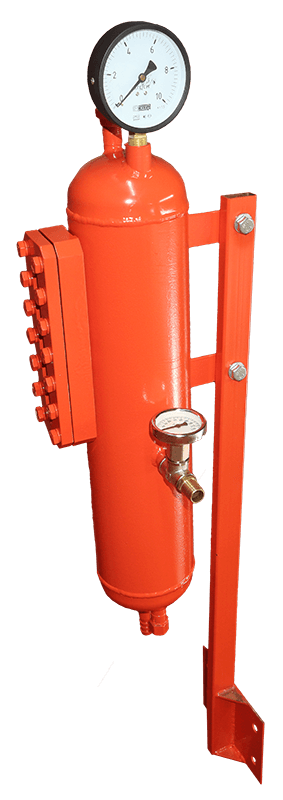

Integral cage for double mechanical seals is equipped with a visual level of fluid control, a pressure gauge and a temperature sensor, designed to ensure the operation of a double end seal. Additional control devices are agreed separately according to the technical specifications.