Belgorod Hydromechanical Plant supplies spare parts for PC pumps.

Spare parts are supplied not only to SP series pumps, but also to pumping equipment that has been modernized by specialists of our company.

Spare parts list:

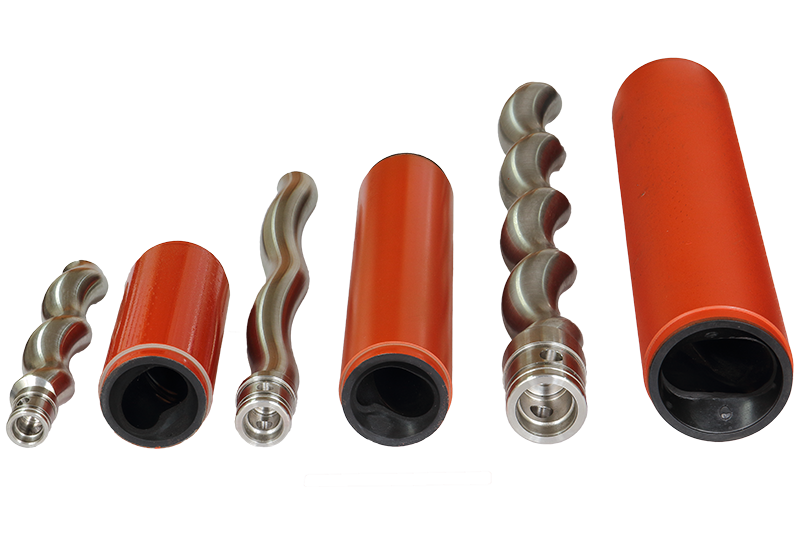

- rotor

- stator

- swivel repair kit

- finger - 2 pcs.

- loop - 4 pcs.

- protective case - 2 pcs.

- locking sleeve - 2 pcs.

- retaining ring - 2 pcs.

- sealing ring - 4 pcs.

- head sleeve - 4 pcs., (from 45 sizes)

- hinge sleeve - 2 pcs., (from 45 sizes)

- articulated shaft

- transition shaft

- mechanical seal

- gland packing seal

The hinge assembly is made of steel 40X13 in accordance with GOST 5632-72 or stainless steel 12X18H10T according to GOST 5632-72 (analogue steel AISI 304). Connection type is closed finger or cardan. The hinge unit works out the eccentricity of the rotor, is filled with lubricant, has a hermetic design.

The protective cover of the hinge assembly is designed to prevent grease from entering the pumped medium. It is made by casting from polyurethane mixtures (alternative to materials based on rubbers). Protective covers of polyurethane are capable to operate in aggressive environments, under conditions of high and low temperatures, high pressures. Operating temperature ranges from -500С to +900С. The advantages of polyurethane include such as high chemical, abrasive resistance, durability, polyurethane does not lose its elasticity, while having increased hardness.

Sealing - stuffing box with graphite packing (NSG). Benefits: low friction coefficient, wide operating temperature range is from - 500C to + 2000C, good thermal conductivity and low heat generation, low probability of flow of the pumped medium between compaction fibers. Operation environment: abrasive and crystallizing media, media with adhesive ability.

All materials coming into production for the manufacture of parts and spare parts of the pump unit have certificates or declarations of conformity, in accordance with the requirements of the current regulatory documents of the Russian Federation.

It is allowed to replace the materials indicated in the drawings with others that do not deteriorate the quality and reliability of the unit and meet the requirements of the design documentation.

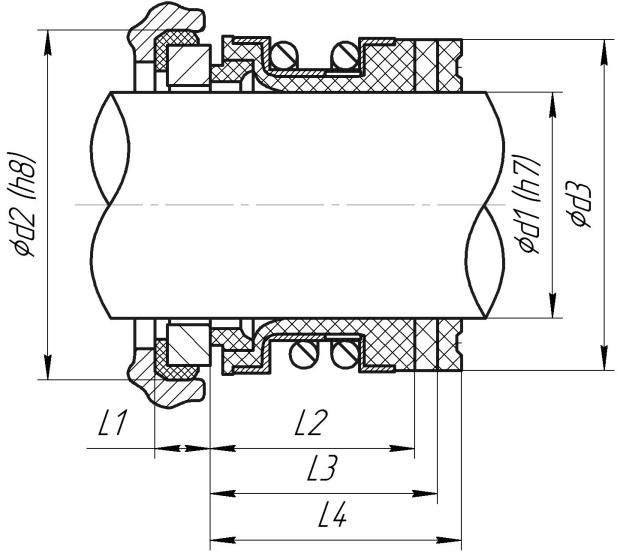

Mechanical seals

The main purpose of the mechanical seal is to seal the transition shaft of the screw pump in order to prevent the leakage of the working medium into the atmosphere.

The mechanical seal consists of two rings of a friction pair, one ring is fixed and installed in the body of the pump end seal, the second is fixed on a rotating shaft. The working surfaces of the friction pair are pressed to each other by a spring. The surfaces of the moving and stationary parts have a perfectly smooth surface, the gap between them remains less than a micron. Also, the design has secondary seals, which provide tightness and are made of various elastomers (NBR, EPDM, VITON).

The cooling of the end seal occurs due to the pumped medium (single end seal) or due to the barrier fluid (double end seal).

Mechanical seals (BSM7N series) supplied by our company are made of the following materials:

- fixed ring (graphite / silicon carbide / tungsten carbide);

- rotating ring (graphite / silicon carbide / tungsten carbide);

- secondary seals (NBR, EPDM, VITON);

- metal parts (AISI304 stainless steel).

Specifications of BSM7N series mechanical end seals:

- fluid temperature - 400С…+1500С;

- overpressure of the working medium in the pump chamber is up to 10 kgf / cm2;

- shaft diameter for the installation of the mechanical seal is 10-100 mm.

Dimensions of the BS2100 series mechanical seals in mm.

| d1 | d2 | d3 | L1 | L2 | L3 | L4 |

| 10 | 20 | 21 | 5 | 15,2 | 27,7 | 35,2 |

| 12 | 22 | 23 | 6 | 15,2 | 26,7 | 34,2 |

| 14 | 24 | 25 | 6 | 15,2 | 29,2 | 34,2 |

| 15 | 25 | 26 | 6 | 15,2 | 29,2 | 34,2 |

| 16 | 26 | 27 | 6 | 15,2 | 29,2 | 34,2 |

| 18 | 32 | 33 | 6 | 20,2 | 31,7 | 39,2 |

| 20 | 34 | 35 | 6 | 20,2 | 31,7 | 39,2 |

| 22 | 36 | 37 | 6 | 20,2 | 31,7 | 39,2 |

| 24 | 38 | 39 | 6 | 20,2 | 34,2 | 44,2 |

| 25 | 39 | 40 | 6 | 20,2 | 34,2 | 44,2 |

| 28 | 42 | 43 | 6 | 26,2 | 36,7 | 44,2 |

| d1 | d2 | d3 | L1 | L2 | L3 | L4 |

| 30 | 44 | 45 | 7 | 26,2 | 35,7 | 43,2 |

| 32 | 46 | 48 | 7 | 26,2 | 35,7 | 48,2 |

| 33 | 47 | 48 | 7 | 26,2 | 35,7 | 48,2 |

| 35 | 49 | 50 | 8 | 26,2 | 34,7 | 47,2 |

| 40 | 56 | 58 | 8 | 30,2 | 37,2 | 47,2 |

| 43 | 59 | 61 | 8 | 30,2 | 37,2 | 52,2 |

| 45 | 61 | 63 | 8 | 30,2 | 37,2 | 52,2 |

| 48 | 64 | 66 | 10 | 30,2 | 35,2 | 50,2 |

| 50 | 66 | 70 | 10 | 30,2 | 37,7 | 50,2 |

| 55 | 71 | 75 | 10 | 30,2 | 37,7 | 60,2 |

| 58 | 78 | 78 | 10 | 33,2 | 42,7 | 60,2 |

| d1 | d2 | d3 | L1 | L2 | L3 | L4 |

| 60 | 80 | 80 | 12 | 33,2 | 40,7 | 58,2 |

| 63 | 83 | 83 | 12 | 33,2 | 40,7 | 58,2 |

| 65 | 85 | 85 | 12 | 33,2 | 40,7 | 68,2 |

| 68 | 88 | 90 | 12 | 33,2 | 40,7 | 68,2 |

| 70 | 90 | 92 | 12 | 33,2 | 48,2 | 68,2 |

| 75 | 99 | 97 | 12 | 40,2 | 48,2 | 68,2 |

| 80 | 104 | 105 | 14 | 40,2 | 47,7 | 77,7 |

| 85 | 109 | 110 | 14 | 40,2 | 47,7 | 77,7 |

| 90 | 114 | 115 | 14 | 40,2 | 52,7 | 77,7 |

| 95 | 119 | 120 | 14 | 40,2 | 52,7 | 77,7 |

| 100 | 124 | 125 | 14 | 40,2 | 52,7 | 77,7 |

Mechanical seals (BSM7N series) supplied by our company are made of the following materials:

- fixed ring (graphite / silicon carbide / tungsten carbide);

- rotating ring (graphite / silicon carbide / tungsten carbide);

- secondary seals (NBR, EPDM, VITON);

- metal parts (AISI304 stainless steel).

Specifications of BSM7N series mechanical end seals:

- fluid temperature -300С…+2200С;

- overpressure of the working medium in the pump chamber is up to 1.8 MPa;

- speed is up to 10 m/s;

- shaft diameter for the installation of the mechanical seal is 10-100 mm.

Dimensions of the BSM7N series mechanical seals in mm.

| d1 | d3 | d6 | d2 | L1 | L2 | f |

| 14 | 25 | 21 | 25 | 35 | 10 | 6 |

| 16 | 27 | 23 | 27 | 35 | 10 | 6 |

| 18 | 33 | 27 | 33 | 37,5 | 11,5 | 7 |

| 20 | 35 | 29 | 35 | 37,5 | 11,5 | 7 |

| 22 | 37 | 31 | 37 | 37,5 | 11,5 | 7 |

| 24 | 39 | 33 | 39 | 40 | 11,5 | 8 |

| 25 | 40 | 34 | 40 | 40 | 11,5 | 8 |

| 28 | 43 | 37 | 43 | 42,5 | 11,5 | 8 |

| 30 | 45 | 39 | 45 | 42,5 | 11,5 | 8 |

| 32 | 47 | 42 | 48 | 42,5 | 11,5 | 8 |

| d1 | d3 | d6 | d2 | L1 | L2 | f |

| 33 | 48 | 42 | 48 | 42,5 | 11,5 | 8 |

| 35 | 50 | 44 | 50 | 42,5 | 11,5 | 8 |

| 38 | 55 | 49 | 56 | 45 | 14 | 8 |

| 40 | 57 | 51 | 58 | 45 | 14 | 8 |

| 43 | 60 | 54 | 61 | 45 | 14 | 8 |

| 45 | 62 | 56 | 63 | 45 | 14 | 8 |

| 48 | 65 | 59 | 66 | 45 | 14 | 8 |

| 50 | 67 | 62 | 70 | 47,5 | 15 | 8 |

| 53 | 70 | 65 | 73 | 47,5 | 15 | 8 |

| 55 | 72 | 67 | 75 | 47,5 | 15 | 8 |

| 58 | 79 | 70 | 78 | 52,5 | 15 | 9 |

| d1 | d3 | d6 | d2 | L1 | L2 | f |

| 60 | 81 | 72 | 80 | 52,5 | 15 | 9 |

| 63 | 84 | 75 | 83 | 52,5 | 15 | 9 |

| 65 | 86 | 77 | 85 | 52,5 | 15 | 9 |

| 68 | 89 | 81 | 90 | 52,5 | 18 | 9 |

| 70 | 91 | 83 | 92 | 60 | 18 | 9 |

| 75 | 99 | 88 | 97 | 60 | 18 | 10 |

| 80 | 104 | 95 | 105 | 60 | 18,2 | 10 |

| 85 | 109 | 100 | 110 | 60 | 18,2 | 10 |

| 90 | 114 | 105 | 115 | 65 | 18,2 | 10 |

| 95 | 119 | 110 | 120 | 65 | 17,2 | 10 |

| 100 | 124 | 115 | 125 | 65 | 17,2 | 10 |