Capacity is from 0,5 to 200 m3/h

Output differential pressure is from 6 to 24 bars

Drive power is from 0,75 to 55,0 kW

Rotor speed is from 78 to 578 rpm

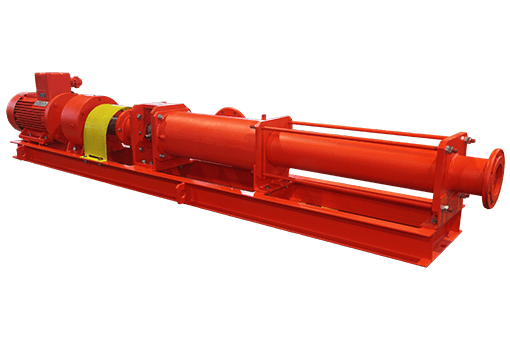

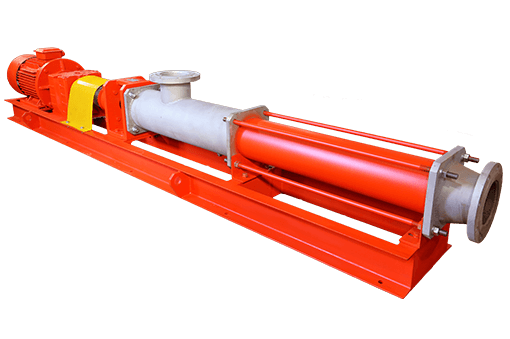

The PC pumps of the Belgorod Hydromechanical Plant (BGMZ) of the SP-H series are the ideal solution for pumping various media, including aggressive, gas-containing, abrasive, and also environments with the highest degree of viscosity with a consistency incapable of fluidity. This type of pumping equipment is unique in its own way. Horizontal PC pumps of volumetric type successfully cope with the pumping of liquid substances containing solids. SP-H pumps have high reliability, they are economical and easy to operate, have high maintainability.

The versatility of the system of the SP series pumping units combines many positive properties of other types of pumps:

- it does not have suction and pressure valves - valveless design;

- the rotor speed is proportional to the feed rate at a stable pressure;

- the possibility to change the direction of fluid flow (when equipped with a special geared motor as agreed with the customer);

- it has self-priming ability up to 8m;

- it pumps inhomogeneous, gas-containing and abrasive media, such as those with strong and fibrous substances with a consistency incapable of fluidity;

- it pumps highly viscous media;

- possibility of use for dosing;

- it does not foaming the pumped substance;

- it operates with different angles.

When choosing PC pumps, the main advantages are the following factors:

- a pump unit is able to pump multiphase mixtures without destroying their structure;

- there is no disruption of supply, as well as refraction in the pressure characteristics with decreasing or increasing speed - smooth operation with reduced performance;

- the work with different angles of inclination in planes does not affect the performance of the unit;

- reliable seals in the absence of any leaks;

- high turnaround time of the main working units;

- pumps do not cavitate when passing air and gas plugs;

- low power consumption when performing similar tasks in comparison with other pumping equipment;

- rotational speed is minimal which increases the service life of the pump unit;

- high maintainability, no need to leave the special service of the manufacturer;

- the ability to control performance at constant pressure;

- low noise.

The principle of pumping is to move the medium by periodically displacing a constant volume enclosed in sealed chambers between the rotor and the stator. When the rotor rotates, the cavity on the suction side increases in volume, and a vacuum is created in it, and the medium being transported fills the resulting cavity under the action of vacuum. With further rotation and movement of the helix, the cavity closes, and the transported medium is moved by the rotor along the stator axis in the direction of discharge.

The rotor and stator is driven by a gearmotor by means of a hinge. The connection of the hinge with the shaft of the motor-reducer and the screw of the rotor and stator is finger or cardan.

The SP series pump units operate in the direction of rotation of the drive shaft indicated by the arrow on the nameplate. All parts in contact with the pumped liquid are made of steel 20, 40Х13 or 12Х18Н10Т (specified when ordering or selecting a pump). The stator is made of elastomer. The elastomer is supplied depending on the pumped medium: food, oil and petrol resistant or abrasion resistant.

SP Pump units are rotating volumetric pumps. The main parts that determine the work process are the rotating part - the “rotor” and the fixed part - the “stator”. Natural wear of the contacting surfaces depends on the number, size and hardness of the inclusions.

The rotor has the shape of an external single-thread helix and is made of high-strength steel with increased hardness. The stator is an internal two-way helix and consists of a metal casing and an elastomer connected to it. When the rotor rotates in the stator, the pumped substance constantly moves from the entrance side to the exit side.

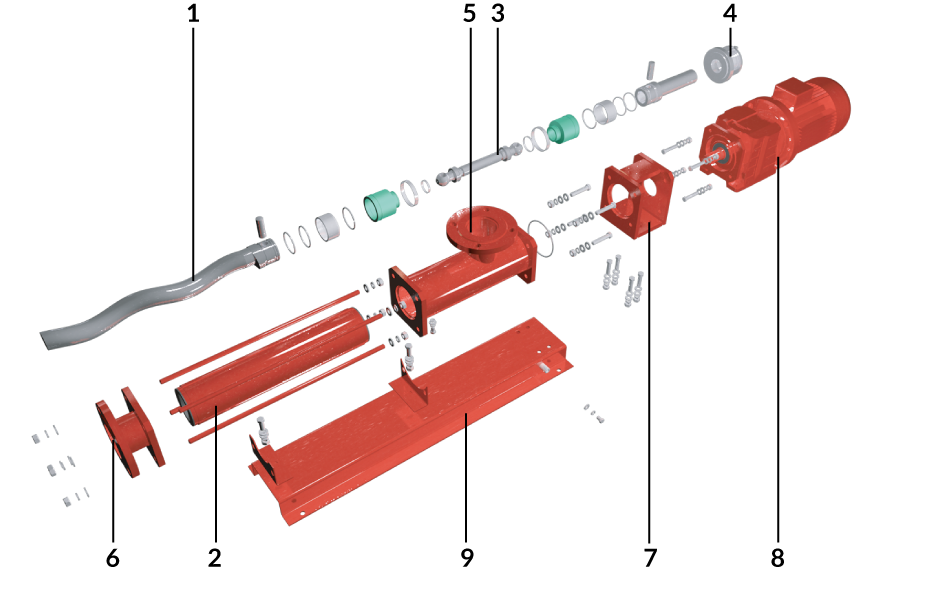

PC pump design

Structurally, the SP series pumping units consist of drive gear motor or variator drive, transition rack, stator pair (stator + rotor), inlet (neck) (pump unit SP-H), output discharge pipe (pump unit SP-H), chamber, hinge and sealing device shaft.

The appearance and components of the PC pump are shown in fig.

1. The rotor is an external single-lead helix with a cross section shifted by the value of eccentricity from the axis.

2. The stator is a double-lead helix, made of elastomer, inseparably assembled with the metal ferrule (sleeve).

3. The joint provides the transmission of torque to the rotor and has a high wear resistance. It is possible to install a auger-type feeder.

4. The shaft seal can be of the following types: serviced gland unit, single end face, double end face, including API.

5. The input, depending on the model of the unit and the customer's desire, is made in the form of a branch pipe with a flange or with a quick coupling connection, or with an input rectangular neck.

6. The output, depending on the model of the unit and the customer's desire, is made in the form of a branch pipe with a flange or with a quick coupling connection.

7. The rack is the base for mounting the drive and the working chamber.

8. Drive - gear motor, motor-variator or hydraulic drive, which gives the required rotation frequency of the rotor and the joint.

9. The frame provides the necessary accuracy of installation of all structural elements of the pump and the rigidity of the attachment to the base or foundation.

The composition of the pump unit includes:

- PC pump;

- reduction gear;

- electric motor;

- frame (pump unit SP-H);

- mounting flange (SP-V).

The package includes:

- PC pump assembly;

- the data sheet of the screw unit;

- the operation manual to the PC pump unit;

- gearbox data sheet, manual (if available);

- data sheet to the electric motor (if available);

At the customer's request, a repair kit of spare parts, frequency converter, idling protection, overpressure protection unit can be supplied for a fee under the relevant contract.

| SP | 1 | - | H | 2 | - | 38 | 3 | - | 01 | 4 | . | SS | 5 | . | 01 | 6 | (Ex) | 7 |

- SP – manufacturer's labelling

- H – horizontal layout of the pump unit

- Rotor Diameter

- Stator and rotor geometry

- Design option:

S – common industrial;

SS – stainless steel. - Type of the shaft seal:

01 – single mechanical seal;

02 – double mechanical seal;

03 – double mechanical seal API;

04 – serviced gland. - Explosion-proof drive